Application and Regular Maintenance of Composite Hoses at Sea

Время выпуска:

2021-02-18

Автор:

Источник:

Абстрактные

When composite hoses are used for loading and unloading oil products between ships at sea, due to the height difference between ships, the composite hoses have a large difference in height during operation, and the oil pressure they bear increases. Therefore, when installing composite hoses, lifting should be done in the corresponding position. When laying composite hose pipelines, the pipes should be straightened as much as possible, and there should be no excessive bending or hard objects touching the pipes. The performance of composite hoses in offshore oil transportation: Composite hoses can adapt to any environment and temperature. When transporting oil and chemical liquids, due to their raw materials and manufacturing process, composite hoses can work for a long time in offshore oil transportation. Composite hoses can still maintain good performance. Kaida brand composite hoses are resistant to gasoline, heavy oil, and can also transport diesel for a long time. These advantages of composite hoses are incomparable to other hoses. Composite hose is a blue multifunctional hose made of high polymer and oil resistant materials, with a long service life and beautiful appearance. Composite hoses, oil hoses, chemical hoses, and hoses can be used in environments and temperatures without affecting the usage characteristics of the composite hoses themselves due to temperature changes. Composite hoses and oil hoses can be made of ordinary materials when transporting oil products, with a pressure between negative pressure of 0.1 MPa and positive pressure of 1.6 MPa. They can transport flammable and explosive liquids such as gasoline and diesel, as well as heavy oil, dirty oil and water. When transporting oil products, the hoses are connected to the inner and outer steel wires and joints, so as long as one end of the hose is grounded, static electricity can be discharged.

The characteristics and characteristics of light oil hoses, composite hoses, and chemical hoses are made using new materials and processes. They are the updated products of rubber hoses and metal hoses. Its main characteristics are: 1. It has good oil resistance and chemical corrosion resistance. Widely applicable for transporting crude oil, fuel oil, food oil, chemical solvents, and liquefied petroleum gas. 2. Has good electrostatic discharge function. When transporting flammable media in oil products, static electricity may be generated due to factors such as pressure, flow rate, and friction. If not exported in a timely manner, the consequences can be unimaginable. This product is supported and connected by double-layer steel wires with inner and outer armor, which has good conductivity and is suitable for use. 3. Lightweight. This product is 40% lighter than rubber hoses of the same specifications and 30% lighter than metal hoses. Reduced the labor intensity of workers, facilitated operation, and improved work efficiency. 4. Good flexibility, flexible bending, not limited by working space. This product can still work normally with a very small turning radius, and in its curved parts, the inside of the tube remains circular, which may cause folding, falling off of the inner wall, and cracking of the tube body. 5. Good resistance to positive and negative pressure. Higher working pressure can reach 4.0MPa, and negative pressure can reach 0.1MPa. 6. Good temperature resistance. The operating temperature is -40 ℃ -180 ℃, and there will be no hardening or softening of the pipe body due to climate or temperature changes. Characteristics of oil hoses: 1. Flexible and flexible. The curvature radius of composite hoses is 1/3 times that of rubber hoses and metal hoses; When subjected to extreme bending, the inside of the pipe remains circular, resulting in folding, falling off of the inner wall, blockage, and cracking of the pipe body. 2. Positive and negative pressure resistance performance. Due to the main skeleton of the pipe being made of steel rings, the working pressure is 0.1MPa-2.0MPa, and the negative pressure can reach 0.1MPa. When the fluid suddenly overpressure, there will be no instantaneous explosion, only creep phenomenon in the pipe body. 3. Good temperature resistance. Under normal use, it can withstand -40 ℃~260 ℃ and will not harden or soften due to climate or temperature changes.

Regular maintenance and repair of oil hoses: Oil hoses should be replaced in a timely manner, and the pipes should be checked regularly to ensure they are still usable. Operators should pay attention to the following signs: 1. Wear or rupture of the outer protective layer. 2. The outer layer of the pipe is cut and exposed. 3. There is oil leakage at the joint or on the pipe body. 4. The flattened part or knotted area of the pipe is damaged. 5. The decrease in oil flow indicates that the pipe is expanding. 6. When any abnormal signs mentioned above appear, the pipes should be replaced in a timely manner. 7. The replaced pipes should be carefully inspected before reuse. Pre factory inspection of oil hoses: 1. Before leaving the factory, all products are tested according to the standard with a working pressure of 1.5 times, as well as conductivity, elongation, and other tests. 2. The blasting pressure/working pressure ≥ the blasting test exceeds the relevant standard requirements. 3. The joint adopts dry sealing to extend its service life and improve performance. 4. The hose joint is replaceable. Diversified product varieties and constantly emerging new products. 5. Provide personalized, comprehensive service application locations: As a soft connection for the transmission of liquid petrochemical media, composite hoses are specially designed and applied in tank trucks, tank storage areas, chemical/refinery plants, petrochemical ships, petrochemical docks, and other places that often require the installation, disassembly, and moving of soft pipes.

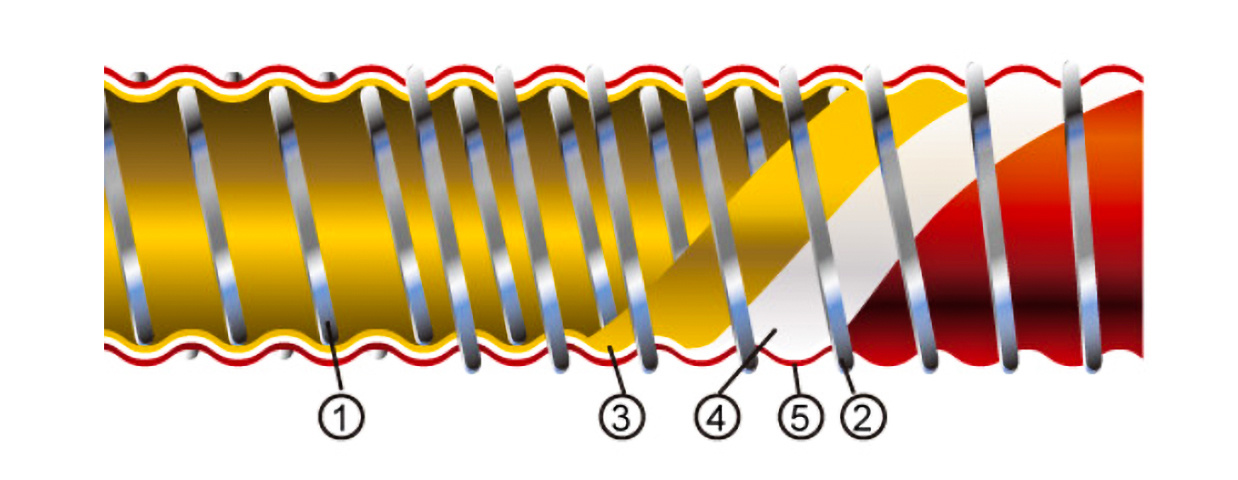

The lightweight composite hose adopts new materials and processes, and is formed as a whole through loose winding of leather wire, sealing with polymer film, and clamping with inner and outer steel wires. Due to the use of technological methods in the development of this product, its characteristics are as follows: ① Lightweight, soft, and flexible in bending. Compared with rubber hoses of the same specification, under the same usage conditions, lightweight composite hoses are 40% lighter than rubber hoses, with a curvature radius of 1/3 times that of rubber hoses. They are lightweight, flexible, and suitable for places with high mobility. Places with frequent dismantling, such as loading and unloading oil tankers and oil tankers. This pipe can also be flexibly used in narrow workplaces, which is incomparable to other pipelines The composite hose has good resistance to positive and negative pressure. The working pressure of this composite hose can reach 1.0-6.4Mpa, and the negative pressure can reach 0.1Mpa (>750mmNg). Under the same conditions, the pressure resistance is better than that of rubber pipes of the same specification. Due to the hardness of the rubber hose, it cannot bear pressure under large bending conditions. When it is extremely bent, the inner wall of the rubber hose folds and blocks the passage. However, lightweight oil hoses still work under extreme bending conditions. At the bending part, the inside of the hose remains circular and will never fold or block. It will not be broken due to extreme bending, which is the performance of lightweight hoses Due to the composition of the composite hose being mainly made of synthetic resin fibers, its resistance to various aromatic hydrocarbons and chemicals is better than that of rubber and metal pipes, especially for some acidic and alkaline liquids where both metal and rubber pipes are not resistant. This pipe can be used to complete the task The composite hose has good temperature resistance and can withstand -30 ℃~180 ℃ under normal use. ⑤ Due to the layered structure of the pipe, there is a phenomenon of expansion and contraction of the pipe body during pressure filling and reducing. Even if the pressure is exceeded instantaneously, there will be no phenomenon of coalescence explosion, but rather the pipe body itself will experience excessive creep. This performance is suitable for monitoring violations of oil diversion tasks using electronic computers in the future and for modern management Equipped with an electrostatic discharge system. When oil flows inside the pipe, static electricity generated due to pressure, flow rate, collision with the pipe wall, friction, and other reasons can lead to fire if not exported in time. When using lightweight composite hoses, only one end of the main pipeline should be grounded with an iron wire to export the static electricity generated during use.

Рекомендуемое чтение