Transportation efficiency and adaptability of composite hoses

Время выпуска:

2021-02-05

Автор:

Источник:

Абстрактные

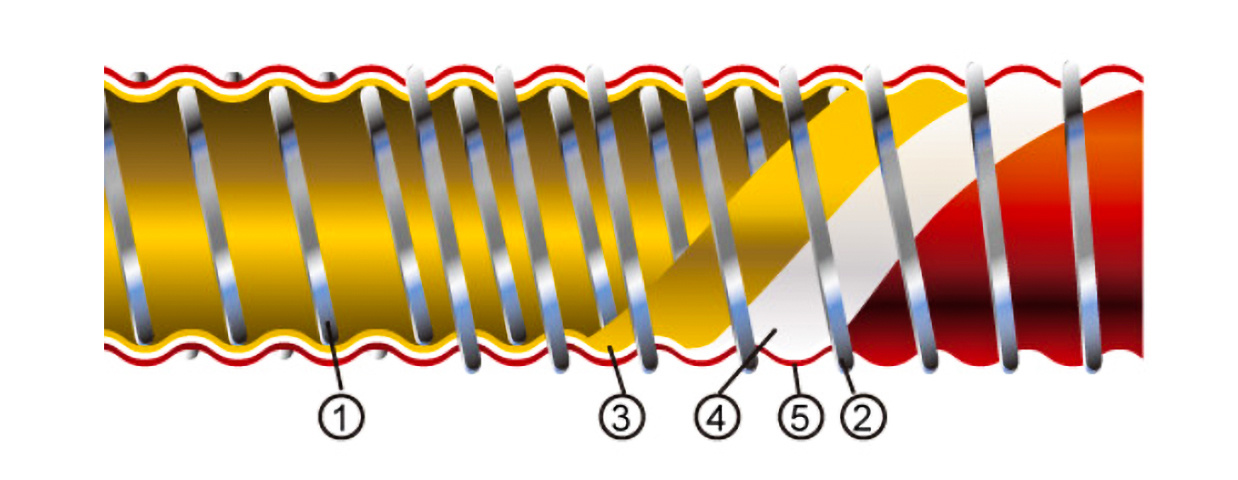

Composite hoses are mainly composed of inner steel wires, reinforced woven layers, sealing layers, external strengthening layers, and outer steel wires. Steel wire wound drilling hoses are used for oil field cementing, well repair, petroleum geological exploration, small drilling rigs and hydraulic coal mining, transportation of mud and room temperature water and other fluid media. Oil delivery hoses also have good chemical resistance properties. Frequent bending will not crack or delaminate, suitable for oil and chemical transportation ships, docks, etc.

Under the same pressure resistance conditions, oil composite hoses are better than rubber hoses of the same specification. It can still work normally with a very small turning radius, and its curved parts always remain circular, without folding, inner wall detachment, blockage, or pipe cracking. Due to the use of laminated galvanized sheet structure, it has better pressure resistance, and there is expansion and contraction phenomenon of the hose during pressure and pressure reduction. Mainly suitable for oil extraction, petroleum refining, sewage treatment, petrochemical storage, animal and vegetable oil storage, shipbuilding industry, oil port terminals, petroleum products aviation fuel oil, etc., it is a popular new type of pipeline in the petrochemical industry.

In order to meet the relevant standards for pipeline quality in petrochemical industry and improve the transportation efficiency of petrochemical products, the following strategies are proposed to ensure the quality of pipeline installation.

1. For the problems that arise during the pipeline production process

In the production process of petrochemical pipelines, construction records should be prepared for each section of the pipeline. After the completion of pipeline construction, the pipeline should be tested according to relevant testing standards to ensure its quality. Timely repair work should be carried out for problematic pipelines to ensure their quality.

2. Solutions to problems in pipeline welding construction

During the welding process of composite oil hoses, the welding work of the pipeline should be carried out according to the welding standards. During the welding process, welding should be carried out according to the specifications of the weld and the markings on the diagram. After welding, strict non-destructive testing should be carried out on the welding surface. After confirming that the entire welding process is qualified, the pipeline should be subjected to heat treatment. The airtightness test of the welding joint is also very important. In the process of inspecting the airtightness of the welding surface, it should be strictly carried out in accordance with relevant testing standards to ensure the quality is qualified.

3. Solutions to pipeline problems

Due to the presence of pipelines underground in petrochemical transportation, they are susceptible to corrosion from underground objects, resulting in pipeline damage. Therefore, we need to carry out the coating work of the pipeline layer according to the standards to improve the service life of the pipeline. In the process of brushing the layer of petrochemical pipelines, two commonly used materials are petroleum asphalt and epoxy coal tar asphalt. These two materials each have their own advantages and disadvantages. Petroleum asphalt has strong pollution and a significant impact on the environment. However, in terms of cost, the cost of this material is relatively low. The cost of epoxy coal asphalt material is relatively high, but in terms of construction technology, it is also relatively much simpler. During the painting process, it should be carried out in accordance with standards to achieve the expected effect and improve the quality of the construction pipeline.

Composite hoses are a widely used product in daily life. It can be seen that they are a type of pipe product with packaging performance, adaptability, and can be used as conveying devices for many products.

In fact, composite hoses have been around for a long time. They are a relatively old product, and with the continuous progress and innovation of technology, more and more excellent products have emerged. Moreover, their functions have become more comprehensive, meeting the various requirements of users.

The composite hoses produced now have many, many characteristics. Firstly, they can withstand high temperatures and cold, and are very suitable for handling because of their light weight and the ability to adjust angles, making them very flexible to use. Mainly used to transport various oils, these characteristics are very good for oil processing.

The production of composite hoses in China has developed a significant market share due to the lack of domestic technology.

The composite hose adopts a multi-layer sealing structure with multiple layers of laminated materials. It has good resistance to cracking and leakage in harsh environments and will not burst suddenly. It can easily handle the transmission of gasoline, diesel oil, crude oil and a variety of chemical liquids. Even in cold weather, it can still maintain high flexibility, light weight, strong toughness, easy handling, soft pipe, flexible use, low temperature, anti-aging, non deformation, exposed inner spiral metal and inner layer, and has static electricity dissipation performance. Therefore, the hose has good pressure resistance. When charging and decompressing, the hose has expansion. When the fluid is instantly overpressure, there will be no explosion, only the pipe itself will experience excessive creep phenomenon. This performance is suitable for modern microcomputer management to complete the operation of transporting oil and gas.

The definition of composite hoses is gradually becoming more generalized, with various manufacturers producing composite hoses that cater to different needs and diversify their products.

Composite hoses are resistant to expensive, high-temperature, flammable, explosive, corrosive, and environmentally polluting liquid gases, as well as oil and chemical substances. Whether it is corrosive sulfuric acid, nitric acid, or flammable and explosive solvents, composite hoses have performance.

Рекомендуемое чтение