Characteristics and chemical resistance requirements of composite hose quick connection device

Время выпуска:

2021-02-22

Автор:

Источник:

Абстрактные

(1) Connection. The guiding mechanism of the composite hose connection device can automatically find the connection endpoint, which is less affected by sea conditions and environment, and the connection alignment is accurate; By using remote control to operate the hydraulic joint, remote control is achieved to achieve automatic connection and disconnection between the work boat joint and the work boat hose joint. The entire connection process does not require the use of any tools or accessories, thereby reducing labor intensity and improving the connection.

(2) Good sealing performance. The hose connection device receives a heavy hammer through a cable winch and then retracts and pulls the cable. The fixed connection end is accurately aligned with the hose joint, and the sealing ring on the contact surface is tightly pressed, avoiding errors and deviations that may be caused by manual operation. During the locking process of hydraulic joints, the mating surface is uniformly compressed, avoiding the possibility of uneven compression caused by manual locking. The sealing performance of the hose joint connection can prevent the leakage of the conveying medium and pollution of the marine environment.

(3) Good resistance to eccentricity. Using a hose connection device, the sealing ring embedded on the fixed pipeline joint and the contact surface of the hose connection end are tightly pressed, with sufficient compensation, and good sealing and pressure retention performance under eccentric load.

4) It can be good. The use of a hose connection device ensures accurate alignment of the hose joint, which is then locked by the thread after being tightly attached. After repeated use of vulnerable parts (springs, mandrels, etc.), there was no damage, jamming, or severe wear, and the connection and detachment of the hose were still smooth.

The hose connection device adopts a hydraulic joint, which automatically connects the conveying hose joint with the fixed joint and locks it, completing the connection between the conveying hose and the fixed joint.

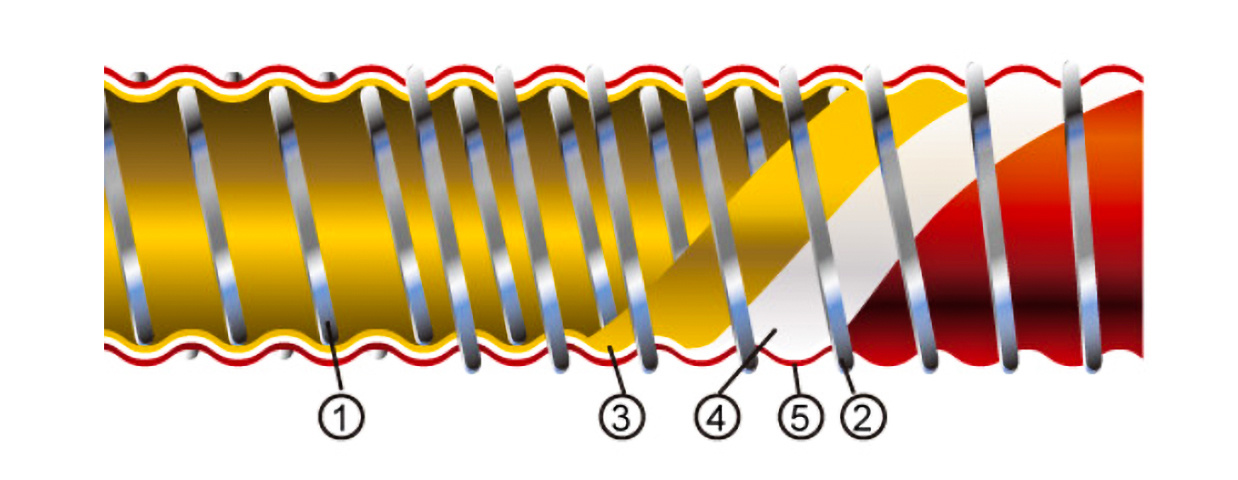

The hydraulic joint is composed of hydraulic rotary cylinder, outer nut, clamping mechanism, fixed joint, and control system.

(1) Hydraulic rotary cylinder. Provide power for connection and disconnection.

(2) Coat nut. The outer nut receives the power transmitted by the hydraulic rotary cylinder and, with the assistance of the spring, engages the external thread of the hose joint through the internal thread.

(3) Compression mechanism. The tail end face of the outer nut is pressed towards the positioning surface of the fixed hose pipe joint to complete the automatic connection work. The outer nut continuously meshes with the thread of the hose joint, and at the same time, the end face of the hose joint moves axially, continuously compressing the sealing ring to achieve a sealing effect through deformation. At this time, the clamping force needs to overcome the weight and sealing pressure of the hose and material in order to prevent leakage of the conveying medium.

(4) Control system. Using remote control operation to achieve long-distance connection and disconnection.

The environmental friendliness of composite hoses should not only include the disposal of packaging waste, but also the pollution to the environment and the resources consumed during the production process. The introduction of composite hoses and all plastic PE composite hoses largely uses economical and easily recyclable sheets in production. When other high barrier materials such as ethylene vinyl alcohol copolymer are used in composite hoses, aluminum foil can be replaced, and composite hoses can be recycled and conducive to biodegradation.

We have made a lot of efforts on composite hoses now, and our products are used in multiple industries. However, compared to aluminum-plastic composite pipes, all plastic composite pipes have some differences in extrusion resilience and barrier properties, which will still limit the process of replacing aluminum-plastic composite pipes with all plastic composite hoses for a considerable period of time. So there are also many classifications of composite hoses.

With the development of industry, various products required in engineering are more stringent than those used in other places, especially compared to civilian hoses. With the complexity and harshness of industrial operating environments, equipment also has stricter quality requirements for hoses. Therefore, it is necessary to standardize and standardize the production process. The use of industrial hoses is very extensive because the different uses in different places also require high chemical resistance of hoses.

In today's world, we use various types of pipes in our lives, with different forms and materials. But most people believe that they are not familiar with chemical hoses and even rarely use them, but in fact, this is not the case.

There are three basic types of chemical hoses, namely heavy-duty chemical hoses, standard chemical hoses, and lightweight chemical hoses.

Heavy duty chemical hoses are specially manufactured for certain projects, using materials that are currently very popular in the world. They have excellent performance and convenience, and are suitable for high-pressure, high drop, and windy work.

Standardized chemical hoses are a cost-effective composite hose that can transport most chemical liquids under normal transportation conditions.

Рекомендуемое чтение