The advantages and process structure of composite hoses

Время выпуска:

2022-09-06

Автор:

Источник:

Абстрактные

Advantages of TAIEN composite hoses:

Tyne composite hose is light in weight, strong in toughness, easy to handle, flexible in use, resistant to high temperature, low temperature, aging, deformation, corrosion, exposed inner spiral metal wire and special inner layer, and has reliable static electricity dissipation performance.

The application scope of TAIEN composite hoses:

TAIEN composite hoses have been used to replace traditional rubber and metal hoses in fields such as docks, oil tankers, petrochemical storage, tank trucks, and chemical plants due to their many advantages such as chemical resistance, safety, flexibility, lightweight, easy handling, and durability.

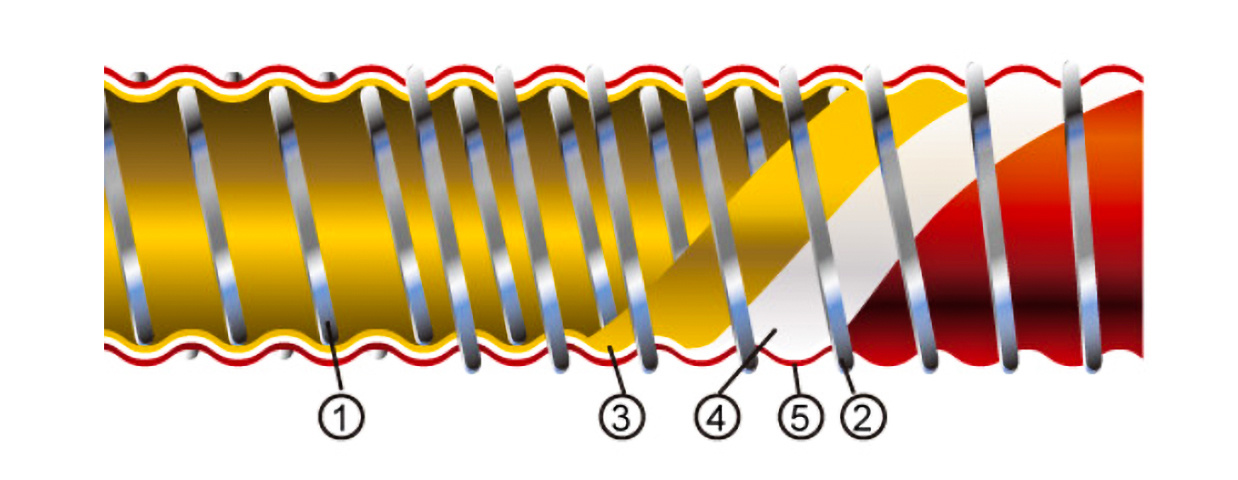

Material and process structure diagram of TAIEN composite hose:

① Inner spiral steel wire ② Outer spiral steel wire ③ High barrier inner layer ④ Strengthening layer ⑤ Anti aging outer coating

Flexible hose structure

The tube body is composed of multiple layers of functional polymer film and synthetic fiber fabric reinforcement layer. The inner and outer layers of spiral metal wires are wrapped firmly

Inner spiral steel wire: usually stainless steel, galvanized steel, aluminum alloy, polypropylene or TEFLON coated steel wire

Outer spiral steel wire: basically stainless steel or galvanized steel wire is selected

Inner lining layer: Functional films such as Teflon Pohetilene Nylon PET are selected based on the characteristics of the conveyed materials. Through proprietary technology composite, the hose has broad liquid resistance and sealing performance

Reinforcing layer and anti-aging outer layer: the reinforcing layer provides the pressure bearing strength for the hose, and the outer layer of the hose adopts the anti-wear and anti-aging color outer layer

Рекомендуемое чтение