Characteristics and chemical resistance requirements of composite hose quick-connect device

Время выпуска:

2021-02-22

Автор:

Источник:

Абстрактные

(1) Connect. The guiding mechanism of the composite hose connection device can automatically find the connection point, which is less affected by the sea conditions and the connection is accurate and accurate; the remote control hydraulic joint is used to realize remote control and achieve automatic connection between the working boat joint and the working boat hose joint. Connect and Disconnect. The whole connection process does not require any tools and accessories, thereby reducing labor intensity and improving connection.

(2) Good sealing performance. The hose connection device receives the heavy hammer through the cable winch and then pulls the cable. The fixed connection end and the hose joint are accurately aligned, and the sealing ring on the contact surface is pressed tightly, which avoids errors and deviations that may be caused by manual operation. During the locking process of the hydraulic joint, the pressure on the joint surface is uniform, which avoids the uneven pressure caused by manual locking.

(3) Good eccentricity resistance. The hose connection device is adopted, and the sealing ring built into the fixed pipeline joint and the contact surface of the hose connection end are tightly pressed, with sufficient compensation, and the sealing and pressure keeping performance is good under the action of eccentric load.

(4) can be good. The hose connector is used for accurate alignment of the hose connection device, and it is locked by the thread after the alignment is tight. After repeated use of wearing parts (springs, mandrels, etc.), there is no damage, jamming, serious wear, etc., and the connection and disconnection of the hose is still smooth.

The hose connection device adopts hydraulic joint, which automatically connects the delivery hose joint and the fixed joint and locks it to complete the connection between the delivery hose and the fixed joint.

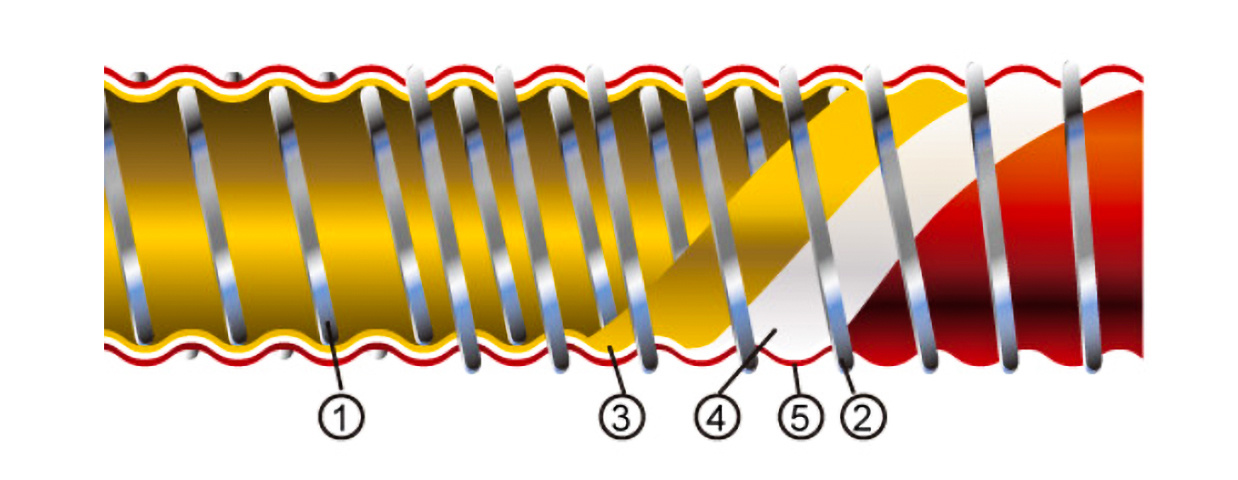

The hydraulic joint is composed of a hydraulic rotary cylinder, a casing nut, a pressing mechanism, a fixed joint and a control system.

(1) Hydraulic rotary cylinder. Provides the power to connect and disconnect.

(2) Outer nut. The outer nut receives the power transmitted by the hydraulic rotary cylinder, and engages the outer thread of the hose joint through the inner thread under the assistance of the spring.

(3) Compression mechanism. The end face of the end of the jacket nut is pressed against the positioning face of the fixed hose and pipe joint to complete the automatic connection work. The outer nut and the thread of the hose joint are continuously engaged, and the end face of the hose joint moves axially to continuously press the sealing ring to deform it to achieve the sealing effect. At this time, the pressing force must overcome the weight of the hose and the material and the sealing pressure to prevent the leakage of the conveying medium.

(4) Control system. Remote control is used to realize long-distance connection and disconnection.

The environmental protection of composite hoses is not only the treatment of packaging waste, but also includes the pollution of the environment and the resources consumed in the production process. The introduction of composite hoses and all-plastic PE composite hoses uses economical and easy-to-recycle sheet materials to a large extent in production. Aluminum foil, composite hose is recyclable and biodegradable.

Now we have made a lot of efforts on composite hoses. Our products are used in many industries. Compared with aluminum-plastic composite pipes, all-plastic composite pipes have gaps in extrusion resilience and barrier properties. This will still limit the progress of all-plastic composite hoses to replace aluminum-plastic composite pipes for a long time. Therefore, there are many types of composite hoses.

With the development of industry, the various products used in the project are stricter than those used in other places, especially compared with civilian hoses. With the complexity and harshness of the industrial operating environment, the quality of the hose The requirements are also more stringent. Therefore, it is necessary to standardize and standardize the production. The scope of use of industrial hoses is very wide, because the chemical resistance of the hose is also high due to the different uses of the place where it is used.

In today's world, we use all kinds of pipes in our lives, with different forms and materials. But most people think they don't know about chemical hoses, or even use them rarely, but that's not the case.

There are basically 3 types of chemical hoses, namely heavy chemical hoses, standard chemical hoses and light chemical hoses.

Heavy-duty chemical hose is specially manufactured for some projects. It is made of the most advanced materials in the world. It has the characteristics of good performance and convenience. It is suitable for high pressure, high drop and heavy wind and waves.

Standardized chemical hose is a cost-effective composite hose, which can transport most chemical liquids under normal transportation conditions.

Рекомендуемое чтение